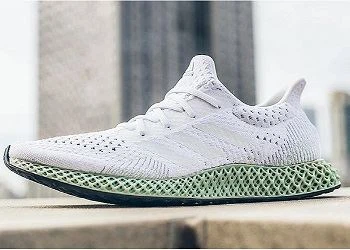

Flexible TPU 3D Printed Shoes SLS 3D Printing Rapid Prototypes Sole

Product Introduction

Our advantage is to have a unified brand image system, marketing system, and standard training system to ensure the reputation of our MJF PA12 MJF PA12 GF, Metal 3D printing Impeller, Multi jet fusion 3D printing. Our company has strong research and development strength, rich manufacturing experience, advanced technology and equipment, reliable quality, and thoughtful after-sales service, and is trusted by users. We should take the improvement of employee welfare and salary as an important means to enhance the competitiveness of enterprises. Through continuous innovation and improvement of the quality assurance system, we can meet different product design needs and provide customers with high-quality services. We are committed to becoming an industry leader with international influence, earning the respect of society through innovative technology and dedicated service.

3D printing shoes made of TPU material are Soft and durable, also recyclable. The outsole structure designed by 3D printing increases the flexibility of movement and greatly reduces the cost and time of personalized shoe production

|

|

Product Details

Product Name:3D Shoes

Material: TUP

Process:SLS/DLP 3D Printing

Printing Machine: EOS P500

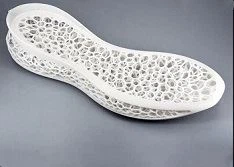

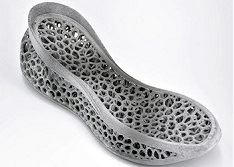

Thermoplastic elastomer material is used in SLS/DLP 3D-printed sneakers that combine strength and flexibility with optimal comfort. Complex constructions that maximize shock absorption while reducing shoe weight can be created via 3D printing.

The midsole, which makes up the majority of sports shoes, needs to perform well in terms of cushioning. Elastomer lattice structures are typically found in 3D-printed soles. The impact force during movement can be distributed more evenly with this open mesh construction. For support and stability, the denser mesh structure in the centre is particularly beneficial. Lightness on the feet.

|

|

|

Feature of SLS/DLP

(1) Excellent wear resistance

(2) Tensile strength and elongation

(3) Oil resistance and gasoline resistance

(4) Low temperature resistance, weather resistance and ozone resistance

(5) Hardness from 50 degrees to 130 degrees

The Application

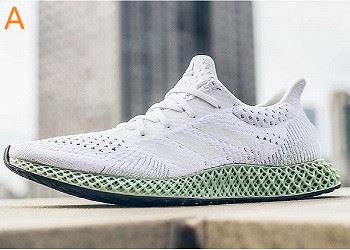

A.3D printing sneakers

B.3D printing barbie shoes

C.3D printing mini sneakers

D.3D printing slippers

|

|

|

|

FAQ

Q. Are you a factory or trading company?

A: We are an additive manufacturing factory with more than 10 years of experience.

Q: How do you print shoes in 3D?

A: By supplying your 3D file, you can now print your own shoes. With our expert 3D printers, you may get your parts in a matter of days.

Q: How much do 3D Printing Shoes made Of Tpu Material?

A: According to your 3D file and the needed materials, we can provide an accurate quotation.

Q: How long does it take time?

A: pls see below information

Delivery Ways | Delivery Time |

Express(DHL,UPS,TNT,Fedex) | About 2-3days |

Air time | About 5-7 days |

Sea time | About 25-35 days |

Production days | About 1-4 days after getting payment |

Packing Way | Bag/Carton/Pallet ect. |

Our company has many years of practical experience and the introduction of professional and technical personnel. On the basis of continuous examination and borrowing of advanced technology at home and abroad, we give full play to our talent advantages and develop a number of Flexible TPU 3D Printed Shoes SLS 3D Printing Rapid Prototypes Sole. We can design the most economical and optimal product solutions according to the different needs of our customers. We take the client first and sincere cooperation as our principle, and sincerely look forward to communicating and cooperating with you and developing together.

Hot Tags: 3d printing shoes made of tpu material, China, suppliers, manufacturers, factory, customized, price, quotation, Inconel Alloy 3D Printing, MJF Technology MJF Manufacturing, FDM 3D printing Large parts, Medical 3D Printing, 3D printing Nylon glass fiber, hp multi jet fusion technology

SPEC DATA

Send Inquiry